JAB SAFETY PTY LTD

Electrical Testing Subject Matter Experts in Newcastle & Surrounds

You must have all electrical equipment examined and regularly tested by a qualified inspector as a business owner. We use cutting-edge technology to offer you the most efficient and effective service possible.

How We Operate Our Electrical Test & Tagging Services

Various factors influence whether or not an appliance will pass the test and tag inspections. We can identify whether the appliance's integrity has been damaged by putting it through a series of tests and then take steps to fix it or remove it from service to avoid an incident or harm.

Using innovative portable appliance testing equipment from Pro Tag & Seaward, we will execute a mix of the following tests and inspections, depending on the appliance.

- Physical Inspection

- Insulation Tests

- Earth Circuit Test

- Continuity Test

- Functionality Test

- Run / Leakage Test

- Polarity Wire Test

- Visual Inspections

3-Phase Test & Tag

While 3-phase appliances are not often portable, they are susceptible to environmental damage and wear and tear of moving components, necessitating testing and labelling. JAB Safety Services uses specialist equipment to test three-phase appliances, ensuring that the tested and marked products are safe for your employees.

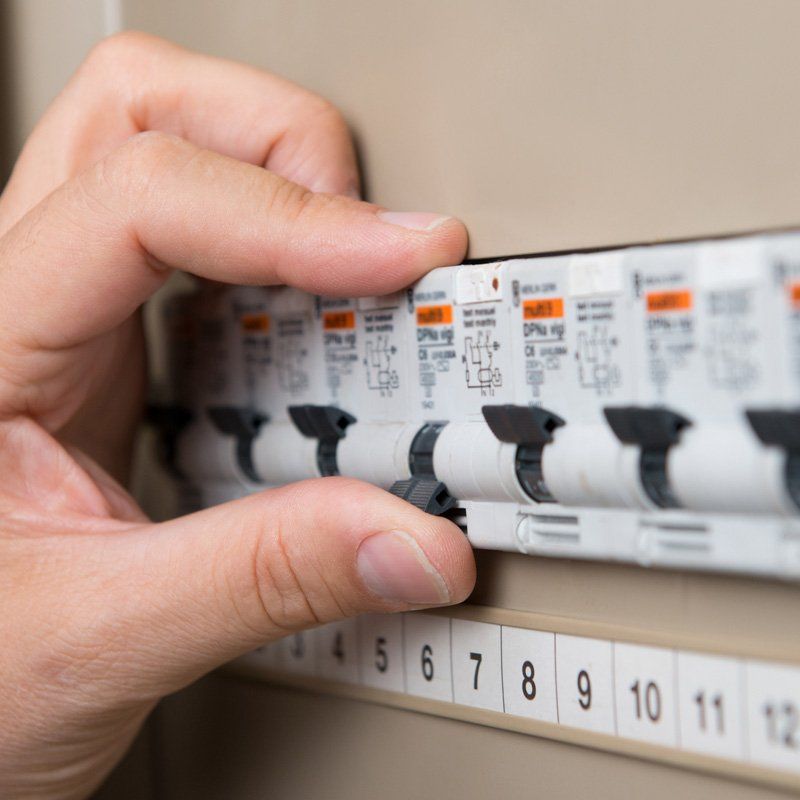

RCD/Safety Switch Test & Tag

JAB Safety Services tests and tags all Residual Current Devices (RCDs) and earth leakage circuit breakers for every organisation and sector. RCDs must be installed on all electrical circuits and must undergo specific trip time testing. This assures that the switch will trip power before major harm or death occurs in the event of an occurrence. The majority of RCD defects are caused by dust and moisture accumulation, so all RCDs should be inspected and tagged regularly.

Minor Repairs (Appliances)

We will also advise you of the faults and damage to your appliances that cannot be fixed on site, and help you determine the best course of action

We repair equipment faults onsite such as:

- Replacement of male and female plug ends

- Replacement of damaged leads

- Refit and re-anchor existing leads

Why Choose JAB Safety Pty Ltd?

Providing 2D barcode asset identification guidance, comprehensive reports of everything inspected and their outcomes and easy-to-read tags. Additionally, you will only be charged for items that pass inspection.

Ready to Get Your Quote?

Need more information? Call us on 0400 205 744 to speak with one of our experts.

QUICK LINKS

CONTACT INFO

Phone: 0400 205 744

Email: admin@jabsafety.com

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Appointment Only

PAYMENT OPTIONS